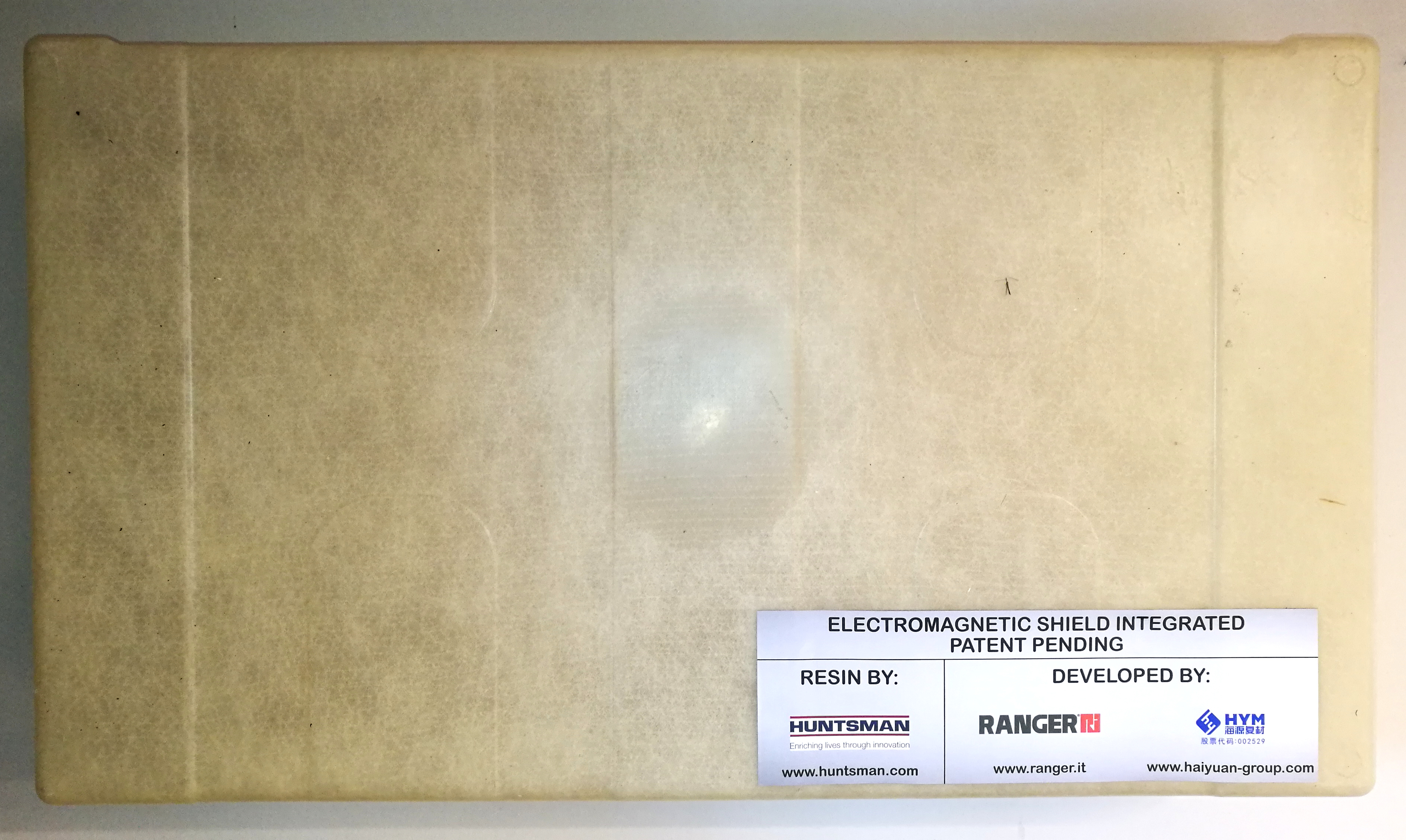

At first glimpse at the trailblazing use of composite integrated with metallic foil for the cover of the battery box. This has the potential for changing the e-mobility industry

RANGER a leading company of plastic and composite materials for the automotive sector at international level has patented a new in-house technology for the cover of the battery box suitable for any type of electric car. The innovation is provided by the material used – the composite – which integrates into the fiberglass structures a metallic foil for the shielding of the electromagnetic emissions released by the battery. The cover is produced with the HP-RTM (high-pressure resin transfer molding) process – which RANGER has been one of the first to adopt and it is now largely used in its factory. For this cover box, the design structure, the resistance to high temperature, the withstanding ability to any chemical leakage eventually released by the battery and the electromagnetic shielding are all achieved with a one-shot process as one molding passage is capable to achieve all the four main features.

“Most electronic vehicles house the battery within the battery compartment in an aluminum box,” says Enrico Ali, the technical expert behind the development of this innovative solution. So far, in fact, aluminum has been largely used because of its ability to protect the battery from external damage and to shield the emissions. “The manufacturing mode of the aluminum material box is usually made of different molding methods,” he continues. “It needs, as such, different processes to achieve all the requirements. While the use of composite with the integrated metallic foil allows achieving the same result in only one.By and large, the advantages are not a few.”

The key distinction is provided by the technology of transformation (HP-RTM) which generates a consistent save of time. “Different molding processes are now replaced with one which is a pivotal improvement to step from small quantities to fully industrialized production,” underscores Simone Pietta, Industrialization & Process Specialist at Ranger. “This also positively impact on the cost of the overall process because it produces savings in the tools used.” As a matter of fact, the tools employed to assemble the aluminum housings have limited durability and so they need constant replacement and continuous investments from the producers’ side. The use of composite provides great protection and can consistently reduce the weight which is crucial for the autonomy of the battery and on the overall asset of the electric car. That was one of the main shortcomings of the aluminum which impairs driving dynamics and vehicle range.The metallic foil already integrated is an efficient solution to guard against electromagnetic emissions. Fields of electromagnetic interference can disrupt the signal flow and can adversely affect the performance of the car. The battery cover offers great versatility as it can be mounted on any type of electric vehicle. But the landmark point of this innovation stands in the great liberty in the designing of the product, especially in terms of shape and thickness. “With composite, we can co-design according to the needs and tastes of our customers- something that could not be done with the previous technology due to the intrinsic characteristics of the aluminum,” explains Ali. In fact, composite can be molded into any aesthetic shapes, and have excellent cosmetic finish with the customers’ choice of painting.

The company, whose headquarter is located in Briosco (Lombardy), has made of the co-design and the customer-specific engineering the core of its business in the past two decades. This thanks to the in – house know-how, developed throughout the years, and with a constant drive for advancement and research of new solutions for its clients. RANGER bases its custom formula on the creativity, skills, knowledge, and resources of its staff which is able to translate an idea to product design and from it the company follows all the process until achieving a ready-for-sale product. As champions of co-design, Ranger has witnessed the powerful impact that the co-design mindset, approach, and tools have had on the outcomes of the work accomplished for the customers.

With this cutting-edge improvement, which is the ultimate outcome of a long series of the breakthrough of its highly competent team of experts confirming the company’s clear vocation for engineering, RANGER confirms to be able to keep up with the fast-changing market of the electric vehicles. There is an increasing demand for electric vehicles and the manufacturing industry across the globe is continuously striving to find cheaper and improved solutions. The newly-designed cover for the battery box might be contributing in the journey towards a world where electric mobility is a choice of millions of people as it promises to provide an integrated, lightweight, high reproducible with shorter cycle times solution consistently influencing the vehicle’s weight and safety.

The patent for the new lightweight cover for battery box has been now deposited and the company has already about five projects underway, but also some further afield.